My MIDI Piano Roll Player project

This project started some years ago when

I heard a player piano playing

A very old song from a small roll of

paper.

I already knew these special pianos but never saw one clearly

sitting close to me. So, I started to have a look inside

the small opening window showing the paper roll

to ‘see’ a small part of its inner mechanism...

So, I started to read and learn about

how these pianos worked

And found a very complex machine... more

complex than

I ever expected.

I said to me Why not play these paper rolls real-time with a stand

alone

micro-processor driven device?

So I started to browse the internet for

any project

that would have been done with mostly the same goal as mine ..

And I found a guy who actually thought about an optical way

to read the piano paper holes instead of using pneumatics

like the original mechanical piano did in the past (and still today).

It used a large row of Infrared LEDS placed in front of the scrolling paper

and around 88 photo-transistors placed inside the brass tracker bar

adjacent holes. It said it chose to use Infrared LEDs instead of

visible colour LEDs because the visible light could actually

go across paper more easily than IR light.

For IR light, paper is like a concrete wall!

And the ambient visible light over the paper could affect

a good and effective reading of scrolling holes.

Unfortunately, its web page with its

project disappeared over time

and I couldn’t go along with what its project came out as a final result...

So…

I had to figure out all the rest by

myself. Good and Challenging!

Ok. First, I had to find a complete

working piano mechanism

to start my project. So, I contacted some piano repairmen and asked

for any remaining mechanism I could salvage for free...

I found a kind repairman who said he

often has these mechanisms

that owners want ‘expelled’ from there pianos.

Sometimes it keeps parts of them, sometimes dumps them in containers!!!!!

Brutal phrase to hear...

Any way I manage to get one mechanism in

very good condition.

Huge thing to bring home... Here are some images of this beast...

The original Beast...

figure 1 – The

complete pneumatics mechanism - front

figure 2 – The

complete pneumatics mechanism - back

figure 3– The

main central paper scrolling unit

figure 4 – The

pneumatic rotating section (5 bellows powered)

figure 5 – The

90 original lead pipes reading vacuum paper holes.

figure 6 - The

original 2 bellows paper auto-centering reading 4 ‘tracking’ holes

Steps involved in this project:

1. Remove

all the pneumatics related parts

2. Remove

all the tracker bar’s lead pipes and clean all its 91 square holes

3. Clean

the brass tracking bar & offset adjustment

4. Design

a main PC board to do all the needed job

5. Write

and compile a prototype software to test all the new parts

6. Install

new 12VDC and 24VDC power supplies

7. Install

both scrolling and centering step motors

8. Testing

both motor’s torque

9. Install

a PLAY/REWIND actuator on front panel

10. Adjusting

scroll motor speeds by standards (software)

11. Make

1,2,3….13 feet marks on test paper roll for speeds adjustment

12. Write

software for paper scroll step motor speed & BPM meter

13. Install

new front BPM indicator using green LEDs

14. Install

all the 91 optical sensors with light pipes

15. Test

all the 91 optical sensor’s gains and accuracy (voltmeter)

16. Test

the 91 optical sensor’s digital reading accuracy (without jitters)

17. Dotted

type lines of long duration notes... how to read them

18. Figuring

out and finalize paper auto-centering mechanism

19. Testing

paper auto-centering mechanism while listening notes (software)

20. Install

MIDI output cable between main PCB and MIDI piano sounds module

21. The

2 x 20 watts power amplifier

*** Remove all the pneumatics

related parts ***

Removing the original lead pipes...

figure 7 – The

original lead pipes before removing...

figure 8 – The dried-out lead pipes

breaking on removal...

Figure 8 left shows how the original

lead + rubber pipes were

very dried out and breaking on removal of the brass tracker bar.

The dried-out rubber parts of the pipes

are the light grey ones.

A card board band was used to align all the 90 pipes

to the brass tracker bar. We can see the remaining lead portion

of the pipes on the upper section of the right picture.

figure 9 – What is left on the tracker bar

back side

figure 10 –

Removing what’s left of the rubber end tied to the tracker bar

On figure 10 we can see how much brittle

the rubbers were...

Bottom picture shows all the ‘almost cleaned up’ 91 tracker bar’s back brass

pipes

tied to their respective 91 aligned front holes.

*** Clean the brass tracking

bar & offset adjustment ***

figure 11 –

Brass tracker bar & offset adjust before cleanup

figure 12 –

Brass tracker bar & offset adjust after cleanup

figure 13 –

Details of some of the 91 brass tracker bar square holes

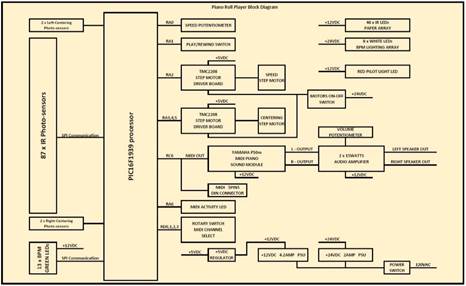

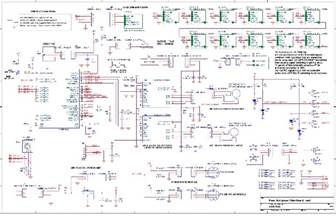

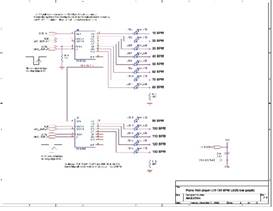

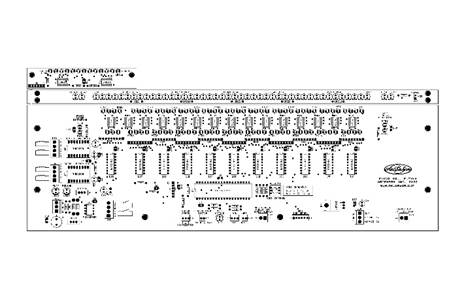

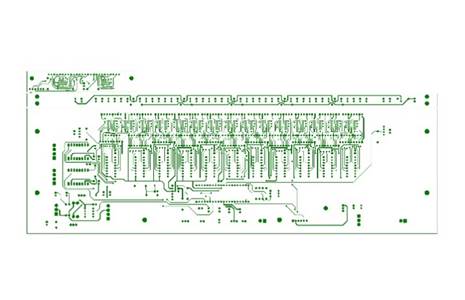

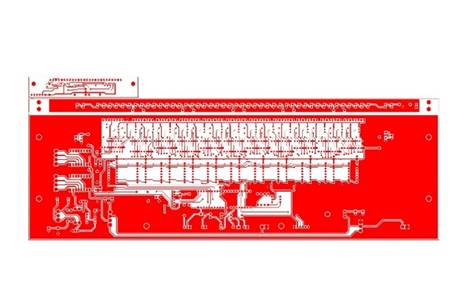

*** Design a main PC board to

do all the needed job ***

figure 14 – A

Complete Block Diagram of the project

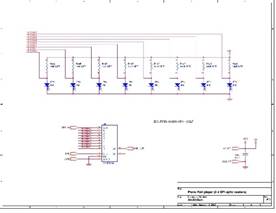

Here are some of the project’s

schematics and PCB’s

figure 15 –

Main micro-processor board with peripherals

figure 16 – One

of the 11 parallel to SPI converters (photo-transistors readings)

figure 17 – The

two SPI to parallel converters (BPM green LEDs)

figure 18 – 48 x IR emitter LEDs array

mounted on liftable hinge

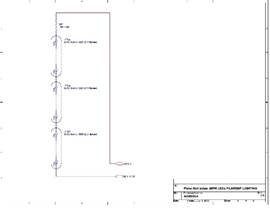

figure 19 – The

three Adafruit 5505 Filament LEDs arrays circuit

figure 20 – The

main PCBoard with IR LED emitters array and small BPM

display board

*** Write and compile a

prototype software for tests ***

All the C code for this project has been

made using Microchip

MPLAB X IDE v5.45 environment. The Micro-controller is a PIC16F1939.

All the detailed source code can be found HERE.

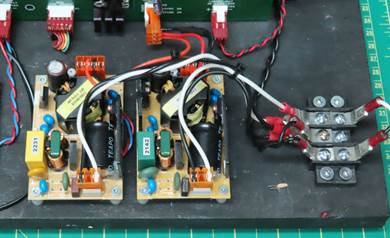

*** New 12VDC and 24VDC power

supplies installation ***

figure 21 – On

the left 12VDC, on the right 24VDC supplies

The 24VDC @ 2.2A power supply is for both

stepper motors and

for the BPM bright white array of LEDs. The 12VDC @ 4.5A supply is used

for the 48 x IR LEDs emitters array including the

Wave Trigger sampler board, The 2 x 20W audio amplifier and the front LED pilot

light.

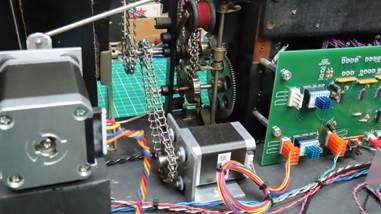

*** Scrolling and centering

stepper motors installation ***

figure 22 – On

the left the paper centering stepper, on the right the scrolling stepper motor

When I started this project, I knew I’d need motors

to run all this machine. I first thought about using DC motors

but these motors would not keep accurately their speed and would

need time to start AND to stop every time they would be powered.

Even with servo control they would also need speed

reduction gears...

So… Why not use stepper motors? They start & stop very fast and are very

precise

on their speed. The only drawback is their torque at high speed.

Well high speed would not be an issue here. I first chose the following stepper motor

A 12VDC Adafruit 324 stepper motor. At 200 steps full rotation

(1.8deg steps)

*** Testing both motor’s

torque ***

The precision was Ok but after some testing’s I found this stepper would not

have

enough torque at max speed on paper scroll. At some points the paper would stop

scrolling...

So, I looked at the other NEMA steppers and found a 200

steps stepper running at 24VDC.

This new stepper was around 5 times stronger than the Adafruit 324 series.

This stepper motor is the SANMOTION

SF2424-10B41

The choice for good stepper motors was now done.

But I faced a new problem... NOISE !

When these stepper motor were directly driven by ‘H’ power transistors

drivers you could hear ALL the steps ‘banging’ one after the others..

Very annoying and not admissible in my type of ‘musical’ project.

So I started to make more readings and found that CRC routers

that uses many stepper motors mainly use some kind of ‘quiet’

intelligent stepper motor driver boards. And these small driver boards are

cheap!

Introducing the TMC2208 -SilentStepStick board.

figure 23 – TMC2208 stepper motor silent driver

After sticking the top heatsink to this small board, wiring it

between the micro I/O pins

and the stepper coils and tweaking its coil current BIAS trimmer

following the PDF instruction

I found it amazing how quiet the stepper motors were now !!

See the previous main schematic for how the wiring to the PIC16 was made.

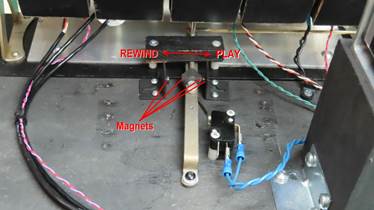

*** PLAY/REWIND actuator on

front panel installation ***

The installed scrolling motor

installation will now need a PLAY/REWIND

actuator to make the paper travel direction job easier. The original direction

changer

was made of a steel rod that would go to far the right side of the keyboard

and actuated by the player manually. I decided to use the same rod but make it

shorter

to be used on my controls front panel. The 4 pictures on Figure 24 show the

setup.

figure 24 –

PLAY/REWIND actuator mechanism

The last picture in figure 24 shows the

use of 4 magnets that made sure the direction lever’s position

would keep its ‘blocked’ position and stay engaged. A proximity switch makes

the interface

with one of the micro-controller I/O pins and makes it

change the scrolling motor direction

accordingly. This is done by changing the ‘direction’ pin signal HI or LO

on the TMC2208 - SilentStepStick board (explained

below) who drives the scrolling motor.

*** Adjusting scroll motor’s

speeds by standards (software) ***

Paper speed standards for player piano are made around units called BPM

or ‘Beat per minute’. So, I need to implement

some kind of software driven pulses to drive the scroll motor

to achieve the needed speeds manually from a ‘step programmed’ potentiometer

placed at the front panel with other controls. The scrolling paper length

will be a fast and precise way to calculate the software’s variables.

To make things easier I first worked on

the paper scrolling stepper.

The paper centering stepper could wait a little later...

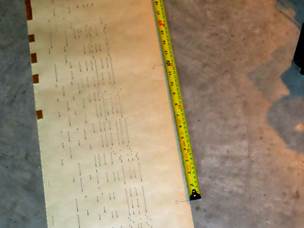

*** Make 1,2,3…. 13-foot marks

on test paper roll for speeds adjustments ***

To get the good MIN/MAX speed needed for the scrolling paper I needed

to check for the player piano roll speed standards which stated:

the minimum speed a roll could go was 10 BPM (10 beat per minute)

and the maximum speed would be 130 BPM (130 beat per minute).

Ok but what about the actual paper length would these be all about?

Well... here the easy answer!

10BPM means 1 feet of paper per minute.

Which suggest 130BPM would be 13 feet of paper per minute.

70BPM here is the most used speed for

many rolls of music.

SO I then decided to use one of my ‘in bad shape’ paper roll

and write marks on it every 1 foot starting from 0 to 14.

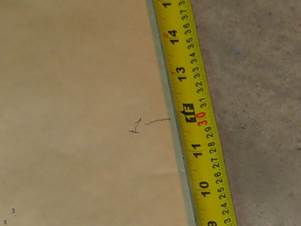

figure 25 – writing marks on every 1 foot length.. up to 14 feet.

*** Write software for paper

scrolls step motor speed & BPM meter ***

*** PLAY position paper scroll ***

Now I could do some speed tests with the scroll stepper motor

by playing with the PIC16 TIMER1 interrupt time

driving it and vary the interrupt time with the help of a ‘Speed’

potentiometer.

The potentiometer’s ADC values are put in a lookup table that

hold all the 13 important ‘delays’ to put in the interrupt function

to drive the stepper motor at the good pace for each of the 13 different BPM

speeds.

Instead of varying the speed continuously on the pot’s wiper I ‘fragmented’ the

ADC readings

by 13 programmed values that correspond to 10BPM at min speed

and up to 130BPM at max in 13 equal rotation steps.

So, I played the marked paper starting

at an unknown slow speed and stop timed

from the ‘0’ mark up to the ‘1’ mark. And wrote the actual time it produced.

For the 10BPM I’d need markings 0 to 1 to take 60sec. precisely.

So, I adjusted the TIMER1 interrupt time

to generate the good timed

stepper motor pulse accordingly. I made this same procedure for all the 13 BPM

speeds.

… Very long and painful work to do

that...

*** REWIND position paper scroll ***

Because the

PLAY and REWIND positions do not use the same roller’s gear arrangement

(Bigger gear on REWIND position... runs

around 5 times faster! )

I could not use the same TIMER1 timings

to drive the scrolling motor

so I calculated a second lookup table to accommodate the slower REWIND timings,

Doing so both PLAY/REWIND positions show around the same paper speeds

when selected by the speed potentiometer.

*** Installation of new front

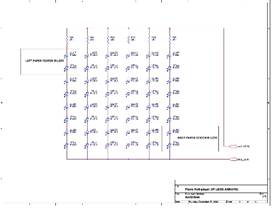

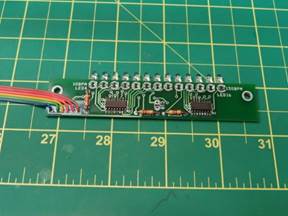

BPM indicator using green LEDs ***

Now that I have a lookup table

containing the 13 scrolling speeds

and selected by 13 ‘fragmented’ potentiometer ADC values,

I could use these 13 ADC pot values to actually select and lite one of an array of 13 front green LEDs

to show the actual selected BPM speed. 13 LEDS would need too many I/O pins

from the PIC16 so I decided to use 2 x external SPI to 8 bits Parallel

peripherals.

74HC595 ICs will be very nice for this

job. 2 of them for 13 LEDs

will only use 3 x I/O pins. Perfect !

figure 26 – The 2 x SPI to 8bits Parallel

ICs 74HC595 mounted on a small PCB

And what about lighthing

this black BPM metal plate ??

Even with a max of 2 BPM green leds lite at a time

this plate sits in a dark area of the lower spool

and is difficult to see even at day light.

And because the upper section of this metal plate needs

to be far enough of the lower spool,

(using ‘fat’ big paper rolls will have tendencies to scrub the metal plate !)

So I had to figure a ‘slim’ way of lighthing.

I thought I could use an array of small LEDs connected in series

and attach them at the front top of the plate, but again

the pcb to hold all these LEDs will still be too big

placed at the top

and could damage the lower paper roll. Then I found this:

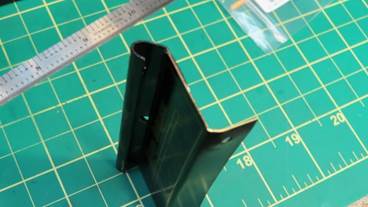

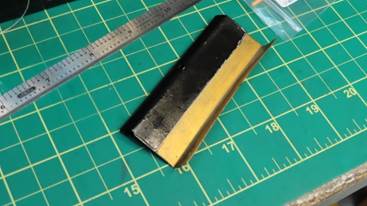

figure 27 – 3 x ‘Filament’ LED arrays

working at 3VDC each.

The Adafruit company sells tinny 360deg glowing LED

array bars (#5505)

that work at 3VDC (30-50mA). These arrays produce a ‘tungsten like’

color that is emitted all around the bar. These bars have a diameter of around

3mm

and could be connected in series with a limiting current resistor to my 12VDC

supply.

So, I designed a thin metal plate that

could hold

and hide 3 of these bars in place and stick the plate at the back top

of the BPM plate. See the following pictures:

figure 28 – 3 x installed ‘Filament’ LED

arrays hidden inside the top curved glued bracket.

A 12VDC connector is ready to be

connected to the back of the BPM plate

to a ‘not shown here’ 2 pins male connector that will

supply around 30mA to the three LED bars through a 100R 1/2w resistor.

figure 29 – The 13 x green BPM LEDs

installed, 70BPM selected, with Filament LED bars at the top

Note: The BPM green LEDs light up ONLY when the PLAY/REWIND actuator is

in PLAY position.

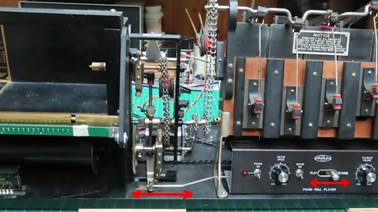

Now that all the paper scrolling

mechanisms have been installed and working

I can start the tedious process of optically reading the brass tracker bar’s 90

holes.

*** Installation of 91 optical

sensors with their light pipes ***

figure 30 –

Cleaning all the 91 tracker holes with Pipe cleaner straw

Since all the 91 holes had accumulated

dust and particles

over their life time it’s time to get them cleaned up.

Figure 30 shows an easy way to get things done.

After a thorough complete clean up of

all the holes

It’s time to start building the 91 optical sensors

or IR photo-transistors and get them inserted in their

respective small brass tubes.

I used a twisted pair length of AWG#22

hookup wire

to wire all the 91 sensors sections:

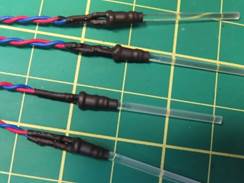

figure 31 –

Twisted pair of AWG#22

figure 32 –

Preparing stuff for 91 sensors

figure 33 –

Still preparing stuff for 91 sensors

On figure 33 you can see inside the left bin 22 x 8pins strips

of 0.1” pitch inline socket connectors. These are from 40 pins strips

cut in 8 pins lengths. 8 pins strips are for 4 sensor wires including their

respective grounds.

See a completed strip here:

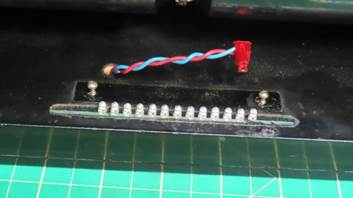

figure 34 –

Detail showing one all the assembled strips for 87 + 4 x IR sensors

Since

8 sensors would need 2 of these 8 pins strips, for 91 (87 + 4 paper edge

detectors) sensors to be installed

I will need 22 x 8pins strips + 2 x 4 pins strips to be assembled.

The last 8pins strip will only provide for 3 sensors (85,86,87) so will be cut

for 6 pins.

The paper’s edge detectors strips only need 2 sensors each so 4 pins each.

*** Test all the 91 optical

sensor’s gains and accuracy (DC voltmeter) ***

Ok. Now that all the needed sensors

strips are assembled, I faced a big problem

about the individual IR beam strength to reach each sensor.

Since the front of the brass tracker bar will be ‘front lite’ by a large array

of 48 x Infrared LEDs,

to perform the optical readings of each paper holes, the emitted ‘band’ of IR

beams from

the front array of LEDs must get through each of the tracker bar’s holes and

reach each

individual photo-transistors (sensors) strongly enough for good ON/OFF notes

separations.

Hope you are still following me here. The problem I faced is that the distance

the front IR LEDs are from each IR sensors exceeds 1.25” in length!

see the picture below.

figure 35 –

Distance the IR beams would need to travel to reach sensors

Since all the

photo-transistors are powered from 5vdc,

with no paper over the tracker bar, and full IR beam strength on the tracker

bar holes

I could not get good photo-transistors saturation but only unexpectable ‘close

to 5vdc’ floating DC voltages

far from ‘saturated’ close to zero-volt readings as it should be...

The solution... Light

pipes installed in front of each IR

sensors to help carry

the tracker bar’s front surface IR beams up to the sensors tips.

Here is a picture of this configuration:

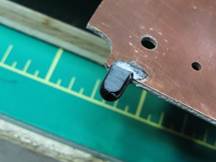

figure 36 – Light Pipes over

IR sensors tip installation details

With these light

pipes installed across each tracker bar holes and their respective sensors I

could see

a very big difference in the sensor’s saturation readings. Very noticeable

ones!

But I noticed that some sensor’s saturated readings were still too high (too

close to 5vdc)

and I wondered why... When checking these sensors, I pulled them out

of their back brass tubes to check their

condition. Oooohhh.

I found these ones had their light pipes cracked or broken in their middle

enough to be seen. Here is a picture one of these broken light pipes:

figure 37 – Broken light

Pipe details

Even a very

small crack in these light pipes caused a very bad IR beam travel attenuation

and would keep the attached photo-transistor from saturate enough

for a good LO digital state. So... I found that I had to replace around 25 of

these

installed light pipes with other good ones. Iark…

These light pipes are made of ‘glass like’ material so they are very brittle.

The 2 following pictures show how the front 48 x IR emitters LEDs array

have been installed.

These are installed on a ‘hinge type’ support which is very handy to correctly

position the array for the very best & strong IR beams over the 91 holes,

and sometimes to lift the whole array for inspection.

figure 38 – Front PCB with 48 x IR emitter

LEDs array mounted on liftable hinge

You can see on the 2 top pictures that parts of the PCB have masking

tapes.

These are sections of the PCB that needed 4 LEDs to be shrunk

and dremmeled to precisely face the far

left/right paper edge holes detectors.

These holes were almost overlapping and very close to each other

which involved 2 pairs of ‘glued’ LEDs to fit the needed IR beams

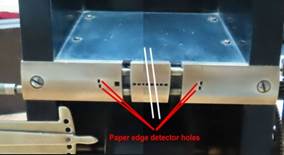

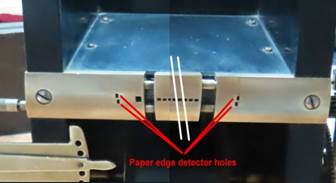

The following picture shows the 4 paper edges detector holes:

figure 39 – 4 x paper edges detector holes

& dremmeled pairs of LEDs details

These modifications were of ‘last minute’ and needed the IR LED pairs

to be glued with epoxy over the PCB LED array left and right sides

facing exactly the edge detector holes.

The

job worth doing it since all the final readings were strong ones.

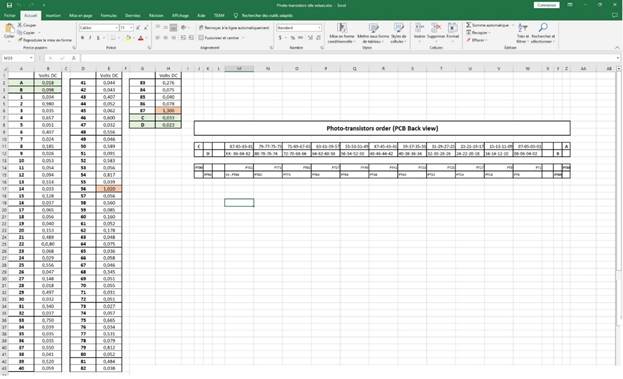

On the following Excel spread sheet you will see how close to zero volt all the

sensors

are with full IR beams crossing all individual light pipes:

figure 40 – Light Pipes installed 91

sensor’s saturation DC values

The Excel spreadsheet shows only 2 sensors that read a little over 1 DC

volt

which is easily saw as 0 or LOW digital level then acceptable.

A diagram of all the 91 photo-transistor positions is also shown at the right

side

viewed from the back of the completed machine.

*** Test the 91 optical

sensor’s digital reading accuracy (without jitters) ***

To perform all the following sensors tests I connected a MIDI external

synth

to the MIDI out connector on the main PCB, set to MIDI channel 2 (the external

synth needed that).

The MIDI channel selector needed to be placed on position 1 (which gave MIDI

channel 2).

figure 41 –

MIDI out channel selector

Now that we know that all the 91 photo-transistors gains are acceptable

and ready to be read with the help of digital micro-controller I/O pins,

we need 87 + 4 x I/O pins to do that job.

Well... no existing micro-controller would ever have this number of I/O

pins available

on one package, so the solution is to use SPI external devices such as the

74HC165

8 bits parallel to serial SPI buffers. They can be daisy chained to be able in

our case

to read all the 87 piano notes sensors. Doing so, only 3 micro’s pins are used.

(The 4 paper edge sensors will be read from standard I/O’s).

So I installed a test paper roll on the machine and did some scrolling and

readings of the first paper’s holes.

After some digital measurements of the actual note’s waveforms acquired from

the PIC16 micro

Instead of reading expectable sequential notes from the scrolling paper I was

getting lot of fast ON/OFF readings

much over the number of notes that were on the paper... Hmmm...

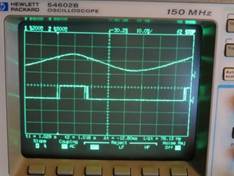

I connected an oscilloscope to one of the PIC16 test-programmed

pins to show in real time

how one of the read holes was ‘seen’ by the micro, and here is what I found:

figure 42 –

Stretched view of one fast going paper hole viewed by the PIC16

Figure 42 first shows the upper trace with a very stretched

up/down 0-5v going pulse that comes from the

tested photo-transistor’s collector. It goes from around 0.5v to 3v max.

The lower trace shows what the 74HC165 related pin sends to the PIC16.

We can easily see the jitters created around where the 74HC165 threshold

level is reached

in the up and down going regions. And these are all these fast-going pulses

that are read

by the PIC16 and added to the normal ON/OFF values that should only be read.

The reason for that behaviour is that the 74HC165 have standard inputs.

These inputs ‘hesitate’ on slow readings around their input threshold values

between LOW or HI to be read.

The solution, to use 74HCS165 chips which have embedded Schmitt trigger inputs.

Using these chips completely got rid of all the jitters. Clean notes readings

now!

*** Dotted type lines of long

duration notes... how to read them ***

Now that I can read paper roll holes correctly with the PIC16 I’m facing

another challenge...

Because of the fragile tendencies of paper roll to break when manipulated some

manufacturers

used ‘dotted’ holes lines for long duration notes instead of steady cut all

over the note duration.

This process is shown on the next picture:

figure 43 – Long duration note

fragmentation of the cutting time to play

Dotted holes lines keep paper in better condition & stronger over

time to be manipulated.

The problem with these successive holes when encountered is that on reading the

playing machine would ‘follow’

these dots as separate notes to play and would create a ‘staccato’ playing

which is not

what the original piano player recorded on paper!

The following picture shows what the PIC16 would ‘read’ when dotted lines are

encountered:

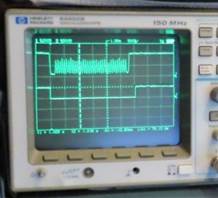

figure 44 – Dotted line reading details

On Figure 44, the upper trace of the oscilloscope screen snapshot shows

one of the photo-transistor’s

collector to its associated 74HCS165 SPI buffer input pin. The optical result

swings from

4vdc (paper blocked IR beam) to around 0.3vdc (full IR beam detected).

You will notice all the small peaks detected over the long note’s duration

until the signal swings back up to 4vdc (ended). These peaks are better shown

on the lower trace

as digital pulses detected from 0 to 5vdc. These pulses would be interpreted as

successive

separated ‘staccato’ notes if not ‘filtered’ with software.

After over 5 days of programming tests I finally figured a way to ‘fill’ these

successive holes

and get a steady note with no fragmentation occurring.

figure 45 –

Dotted line reading with filtered action. One steady note remaining.

The upper trace of the oscilloscope screen snapshot shows one of the

photo-transistor’s

collector to its associated 74HCS165 SPI buffer input pin. Again, the optical

result swings from

4vdc (paper blocked IR beam) to around 0.3vdc (full IR beam detected).

Now the lower trace shows how the software filtered all the incoming peaks

and flattened them out to get a steady and single low going pulse.

You will notice the ending hi going pulse on the lower trace is delayed

compared to the upper trace hi going ‘note ending’ one. This is due to the

software filtering counter

that ‘counts’ for a real end of note occurring before really ending the

incoming note.

*** Figure out and finalize

paper auto-centering mechanism ***

Now that all the 87 notes sensors are read correctly and that the scroll

motor works by the player piano speeds standards

we can focus on how to make the paper scrolling travel with auto-centering.

On playback, when a piano roll is pulled down by the low pulling roller it has

an easy tendency to be

dragged to the left or to the right along its song period. This behaviour

causes the scrolling paper holes

to get unaligned against the tracker bar’s array of holes, then producing

unreliable readings and lots of missed notes.

So, the playing mechanism needs some kind of auto-compensation for the

paper centering

to keep the playing aligned and steady for any playing speed.

figure 46 –

Paper centering original Brass bar holes.. LEFT and

RIGHT

Figure 46 shows 4 x holes dedicated for the paper centering process.

2 for the left readings and 2 other for the right readings.

The original auto-centering mechanism was made using 4 x pneumatic

rubber pipes

connected to a 2 bellows tank that activated left/right movements of the

upper roller

so auto-centering the paper along the playing of a song.

Now I needed to achieve the same auto-centering but optically...

I started using all the 4 edge detector sensors involved and did many tests

that would make me conclude the following:

Over time many of the paper rolls get damaged by dryness and heat. Their

overall width can be affected

and would be hard to rely upon (by the mean of the tracker bar left/right edge

sensors).

And one major thing was the way the 4 edge sensors would respond when the paper

edges

are detected or not when passing over them. I could not achieve the same

reliable work the original 2 bellows pneumatic system would.

I finally determined that using 4 optical edge sensors was not a good way to

auto-center the rolling paper...

So, what else could I do?

I took a piece of paper and started to do binary calculation of how the paper

edges behaves

and some way to reliably ‘track’ the paper drifting’s and stop them along the

played song.

I finally found a very easy way to do it.

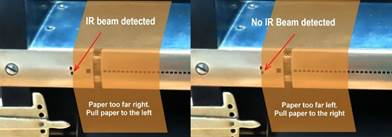

Only use one of the 4 edge detector sensors (the lower left one) and use it as

follow:

The far-left lower edge sensor is used here and will only read HI or LOW from

what’s passed over it. OK.

Just

assume the paper is too far left:

The paper will completely cover the detector hole making a digital HI reading.

Now let’s assume that the paper is too far right:

The paper will not cover the detector hole at all making a digital LOW reading.

This means that the ‘ideal’ aligned

positioning of the paper is where the ‘Transition Zone’ is,

which is an impossible zone to stay on, BUT we can continuously try to reach it

slowly going left – right – left – right -- and so on..

Here is a small diagram of this process...

Transition zone

______________________

_|

HI,

No IR beam so

|

LOW, IR beam passing so

Paper over sensor

| edge too far right that let beam pass

Push paper to the right | Push the paper to the left

|_______________________

The following picture shows the 2 actual paper positions that would imply

a ‘move’ of the centering motor. The 2 positions have been exaggerated

to best show both conditions, but in reality the paper left-right move

on the tracker bar never exceed around 0.5mm which is very good for a tracking..

figure 47 –

Auto-centering detection of paper needing to be re-positioned

Now that the PIC16 has a way to figure where the paper’s edges are

placed on the tracker bar

it can decide how to act to correct the paper left/right position.

The paper position correction is made by the help of a second stepper motor

who’s shaft turns just a little left or right moving a steel rod attached to

the upper supplying roller shaft itself.

The stepper motor speed is programmed to be very low with a calculated inertia

to be not too fast, not too slow.. Just the good correction speed (compared

with a real pneumatic compensation speed).

The following closeup is a view of the back centering stepper motor with its

steel rod attached to

the upper supply roller to adjust its left/right position.

The right image shows the front needle showing the ‘real time’ paper

positioning.

figure 48 –

Auto-centering stepper motor positioning system

Without this auto-centering system I had around 15 piano rolls that

would absolutely

not work on the machine because of their pour paper quality and waving

behaviour while playing.

This auto-centering made them work again flawlessly!

On all the rolls playing I checked the holes alignments for any misbehaviours.

No problem found. I could see the centering stepper motor do its job by

continuously pulling/pushing

the upper supply roller shaft. But... Some paper rolls however need an ‘offset’ adjustment

before starting to play. Their ‘almost the same’ width (compared to other

rolls) needs this tweaking.

This is done with the help of a small screw type slider placed

just above the left transpose key shown here:

figure 49 – Tracker bar offset adjustment

screw

Turning this screw slider makes the complete tracker bar center

move left-right

depending on the direction the screw is turned. The distance moved is just

enough to readjust

the alignment of both the paper holes and those of the tracker bar.

After this offset adjustment nothing more to be done to precisely play that

paper roll.

*** Testing paper

auto-centering mechanism while listening notes (software) ***

Now that I had the paper auto-centering

working I just needed to do a real test with a QRS test paper roll.

This test roll tests all the piano keys successively one after the other. It

also performs big successive chords.

The test passed with success! No notes missed at any speeds! Now I want

an ‘installed’ MIDI sampler player with piano sounds.

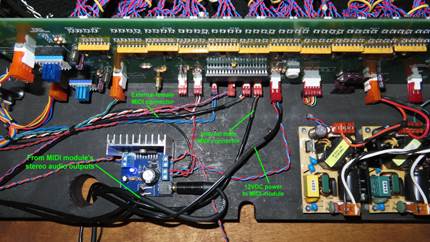

*** Installation of MIDI

output cable between main PCB and MIDI piano sounds module ***

Ok. All the piano roll player is now

working and ready to drive, thru MIDI control,

a small MIDI sound module with piano waveforms installed. My project will be

‘standalone’ and able to play

songs without any other audio device connected... To do that I need a small

MIDI sound module that

can read incoming notes via MIDI protocol. My project offers 2 separate MIDI

outputs.

One connected to the Yamaha P50m for ‘stand alone’ uses via

a DIN male connector connected to its INPUT, and the other MIDI

output is connected to another MIDI female connector for external connections

to any MIDI devices for added sound variety.

Introducing Yamaha P50m piano sound module

figure 50 –

Yamaha P50m module connected to a 2 x 20W power amplifier

The stereo power amplifier outputs were

connected to 2 small MINIMUS 20w sound boxes

that will be attached inside the complete machine’s case.

*** The 2 x 20 watts power

amplifier ***

One note about the TDA7297 based bridge

power amplifier board:

I found that the overall stereo power was easily distorted when pushed a little

on both channels.

So, I checked both +/- leads of each left/right channel output

connectors.

I first connected the – lead of left channel output to my oscilloscope.

GND lead of scope to GND of power amp,

and played a roll. (One side of the bridge output tested).

When powered by a single polarity +VCC, the TDA7297 IC has a bridge output

configuration, so

both + and – output pins of each channel should go from idle VCC/2 volts and up

to around VCC or GND

but inverted together. Well, that’s not what was happening. Only the + output

pin was swinging with music.

The - output pin was stuck in the VCC/2 position... no signal! Same thing on

the right channel.

So the amp was working at a much lower possible output power that it should.

That meant one thing... I had a fake TDA7297 IC on my amp board! This board was

purchased from Aliexpress for $7.00US

So I ordered a genuine one from Digikey, a reliable seller.

Here is a final view of the piano roll player’s front controls:

figure 51 – Front panel controls

While in the design process I found very

cute the old 5 x vacuum bellows activated motor

that originally powered the rollers by the user’s pedal actions and decided

to keep it geared to the scrolling motor mechanism.

This unit still ‘pumps’ air while the machine plays or rewind:

figure 52 – Original 5 x vacuum bellows

activated motor

*** Final cabinet that holds

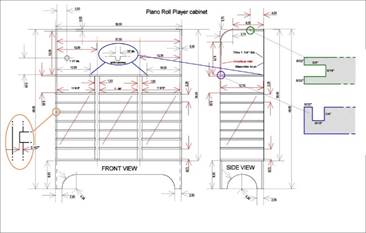

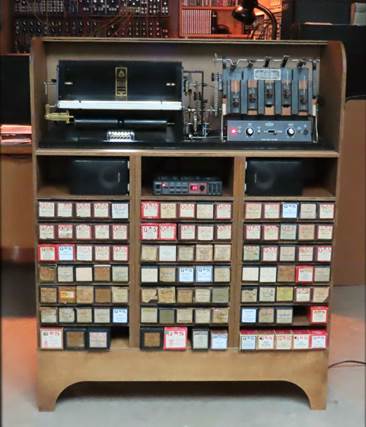

all this project.. ***

This project needed a cabinet to hold all the necessary electronic

hardware

including my collection of around 100 paper rolls I already had.

So I designed a decent cabinet made of ½” Russian plywood

with enough compartments to store the paper rolls.

Here is the actual cabinet drawings and final appearance:

figure 53 – Project’s cabinet drawings and

final appearance.

So that’s it !

Thanks for watching and feel free to ask

any questions

about this project using the email below..

If you’d like to have a look at some of my other projects

Just go to www.arcenson.com/projects

2023